|

SINOM GROUP CO., LTD.

|

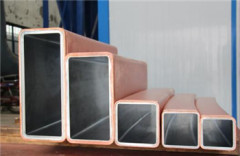

beam blank copper mould tube for continuous casting line to produce steel rails

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

beam blank,

continuous casting line,

steel rails

Copper moulds have played an important role in the development of the continuous casting process .Their function is to receive the molten steel and to allow rapid heat transfer from the steel to the cooling water to enable quick solidification. The mould must exhibit excellent thermal conductivity, be resistant for thermal erosion, and be resistant to distortion from thermal stress.

Mould material:The tough working condition of copper mould tube requires its material with

excellent tensile strength, enough hardness, low elongation & good thermal conductivity. After many years experiment in our Lab & steel mills, now we are manufacturing copper mould tube with widely accepted material as : Tp2, CU-Ag0.1 & Cu-Cr-Zr.

Typical coatings are : Cr, Ni, Cr-Ni, Ni-Fe, Ni-Co

Beam blank copper mould tube specification:

Size: as per customer's drawing, Radius: 6000-17000,Length: 700-1000, Taper deign: triple taper

Multi-taper, parabolic tapers & convex.